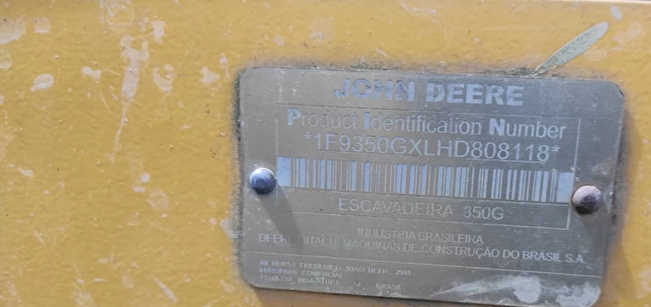

Hello everyone, today we are going to work with the John Deere Service Advisor search engine. We talked about how to start a new job and how to prepare for it. In this video, we will focus on how to create a “new job”. To do this, we must have the equipment plate on hand. Every John Deere machine, whether it is an excavator, tractor or grader, has a black plate located near the cab or in a specific location depending on the type of machine.

It is very important to find this plate because it contains key information to enter the serial number of the equipment. For graders, the plate is located on the front frame, while for tractors, it is located on the rear frame. The plate contains the PIN (Product Identification Number), which is the equipment identification number. For example, this 350G excavator, the serial number starts with “1F9”, indicating that it was manufactured in Brazil.

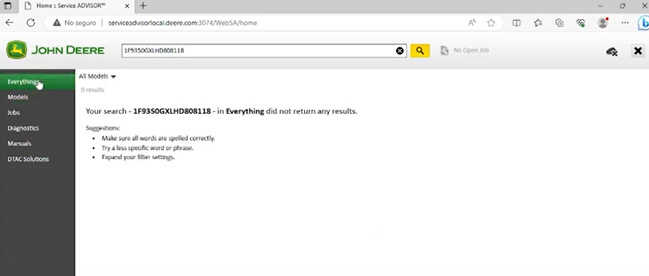

With this information, we will test the Service Advisor search engine by entering the full series “1F9 350G XL HD 8081”. We will see if the system allows us to search for the device using the PIN.

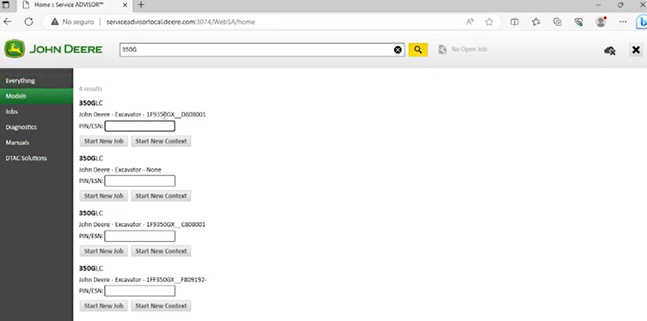

We wait for the system to search for information about the 350G. However, it tells us that it cannot find this machine this way. In this case, we will use a regular search, entering the model number “350G”. Some machines allow the use of the full kit, while others do not, so it is important to try both options.

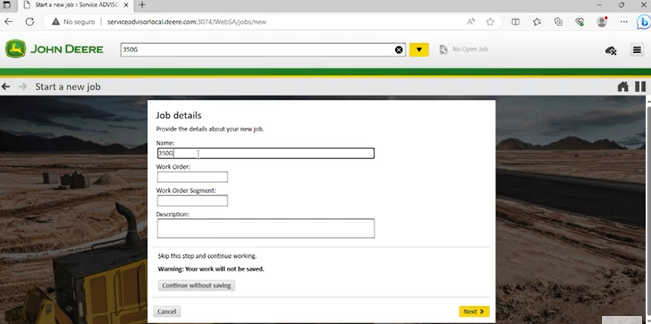

Since our machine has the serial number “1F9”, we select the corresponding option from the list. Now, we start a new job (New Job). In the job details, we can enter information such as the model number “350G”, as well as the reason for the job, such as “Service Advisor Course”. If the work is carried out at a dealer or authorized workshop, it is also possible to enter a work order here for internal control.

If we want to check the engine parameters, we can specify a segment, such as “Engine”. In the description, we can be specific about the problem, such as “Engine does not start”. Then, we go to the next step, where the system will ask us to enter the device PIN. This is essential if we are going to reprogram, because each device has a specific profile.

When you enter the PIN, the system will store it and will not ask for it again when reprogramming. After logging in, the newly created job will be displayed at the top: “350G – Service Advisor Course”. From here, we can access manuals, diagnostics, reprogramming, news and other options, including offline mode.

In the manuals section, we can find detailed information on various components, such as the “6090” engine manual or the basic “401” engine repair manual. There are also documents on electrical connectors and fuel systems, such as the “NAEK Level 14” for common rail systems.

The operation and test manuals provide instructions on how to evaluate the hydraulic system, engine oil pressure and other key aspects. They also include the operator’s manual, which is useful for understanding the operation of the machine and its controls, such as joysticks and travel pedals.

These manuals help the operator identify faults, such as possible leaks in the flow divider. In addition, there are documents on repairing components such as hydraulic jacks and counterweights, as well as detailed information about the chassis and the John Deere JDLink system.

For diagnostics, the device must be connected via EDL (Electronic Data Link). EDL versions 1, 2 or 3 can be used via USB or Bluetooth. Bluetooth connectivity helps monitor intermittent faults without the operator being nearby.

With Bluetooth, we can receive real-time data on the occurrence of faults at a distance of up to 10 meters. This makes it easier to detect error codes and their triggering conditions.

The real-time readings allow us to monitor parameters such as engine speed and pump pressure. If we are online, we can take screenshots and store them in the created work.

The system provides a diagnostic tree that guides you step by step in troubleshooting. For example, if the engine oil pressure should be between 15 and 65 psi, the system will indicate if the value is within the proper range before moving on to the next step.Once the diagnosis is complete, all data is stored in the created job. In the future, if you need to refer to this job, you can access the list of previous jobs within Service Advisor.

This system allows you to manage multiple jobs in an organized manner, view recent changes, and share information with other technicians.

In summary, this was a brief explanation of how to work with a “New Job” in Service Advisor.

More topics for John deere machine,please refer to:John Deere Trouble Repair.