In some repair situations you will need to perform a dead zone adjustment. This post provides a dead zone setting guide for Jungheinrich ETM/V 10-12 forklifts.

Related Contents:

Jungheinrich JETI ForkLift Judit-4 v4.37 4.34 2023 Free Download

The adjustment to the neutra1 zone becomes mandatory when the fo1lowing repairs have been carried out on the motor :

a)After exchanging the commutator bearing plate

b)After displacing or mounting the brush bracket

c)when the armature has been renewed

d)when the field coils have been renewed

Neutral zone setting process

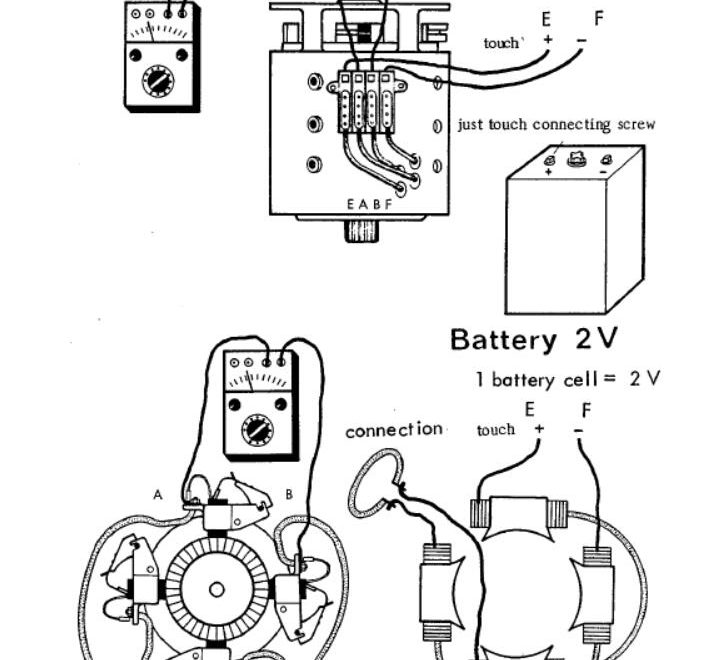

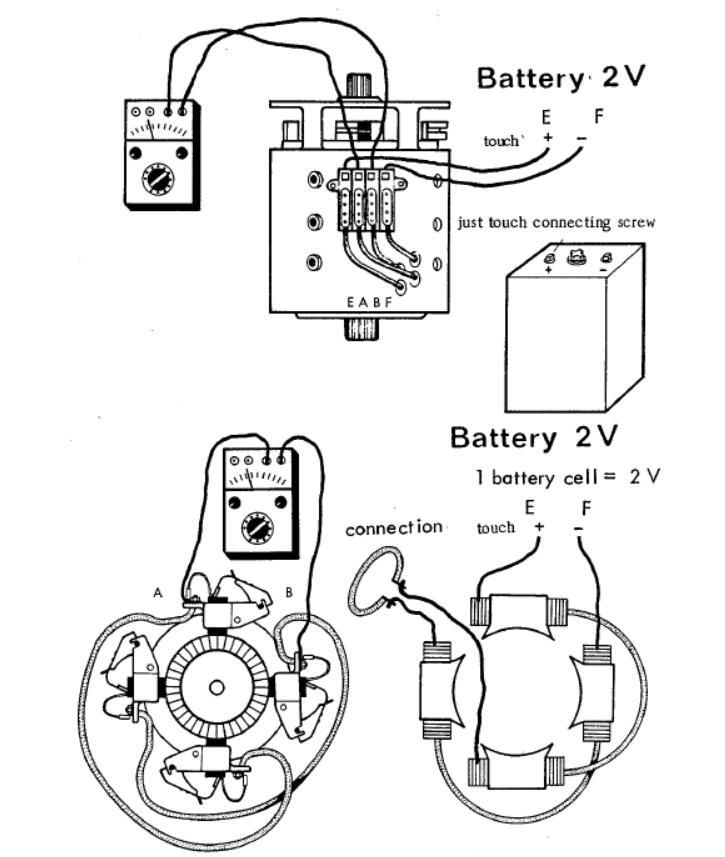

To understand the process better, you can look at the motor as a transformer. The field takes on the function of the primary winding and the armature that of the secondary winding. A multimeter is connected to two side-by-side brushes set to mV or mA AC range.

One of the two field connections (- F) is connected to a 2 V battery cell and the second cable is used to touch the plug pole. This induces a voltage jump in the armature winding. Adjusting the brush holder will reduce the tension to a minimum indicating that the brushes are positioned in the neutral zone.

This applies to drive motors that work in both directions. Pump motors are adjusted accordingly, only the brush holder is set to a commutator segment counter to the direction of rotation to the left, since the pump motor always rotates to the right. In addition, the brush mount field coil connections must be disconnected and externally bridged.

For more Jungheinrich troubleshooting cases, see Jungheinrich troubleshooting